Close

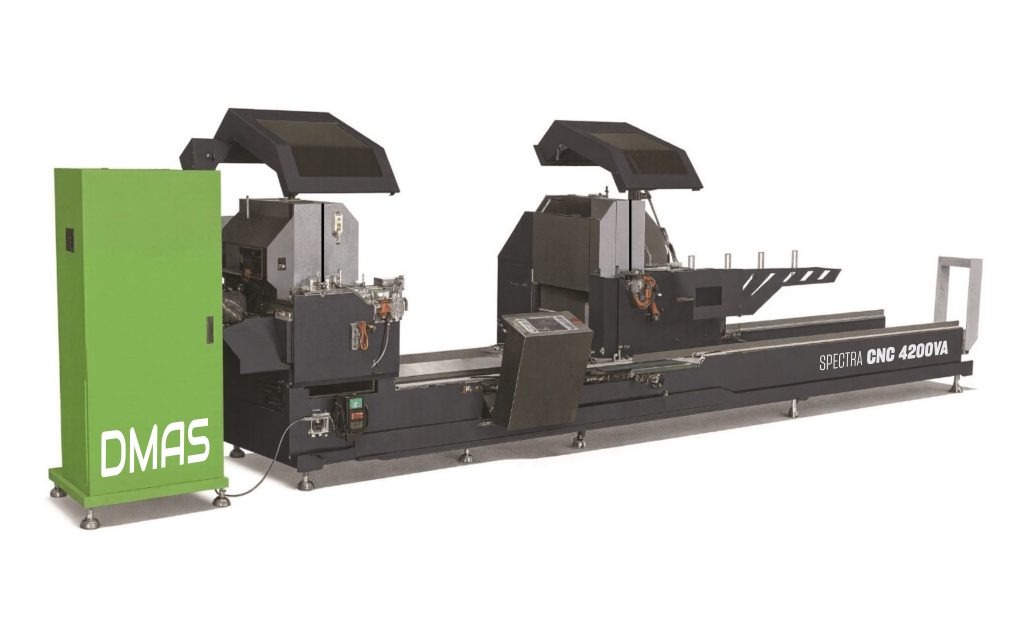

Designed for precision cutting of aluminum alloy profiles—including aluminum door, window, and curtain wall components—this machine delivers exceptional accuracy and performance.

Powered by an imported servo motor and controlled by an advanced CNC system, it allows precise and flexible adjustment of cutting angles between 45° and 135°. This configuration ensures high cutting accuracy, operational stability, and adaptability to meet the demands of complex profile cutting applications.

Specification |

CNC 4200VA-650 |

CNC 4200VA-500 |

|---|---|---|

| Power Supply | 380 V / 50 Hz | 380 V / 50 Hz |

| Cutting Motor Power | 2 × 3.0 kW @ 2800 rpm | 2 × 2.2 kW @ 2800 rpm |

| Working Air Pressure | 0.5 – 0.8 MPa | 0.5 – 0.8 MPa |

| Air Consumption | 60 L / min | 60 L / min |

| Blade Specification | Ø650 × Ø30 × 4.4 mm Z = 144 |

Ø500 × Ø30 × 4.4 mm Z = 120 |

| Cutter Feeding Speed | 0 – 3 m / min | 0 – 3 m / min |

| Cutter Moving Speed | 0 – 20 m / min | 0 – 20 m / min |

| Cutting Length | 430 – 4200 mm | 400 – 4200 mm |

| Cutting Width | 230 mm | 220 mm |

| Cutting Height | 190 mm | 170 mm |

| Cutting Angle | 45° – 135° (Any Angle) | 45° – 135° (Any Angle) |

| Overall Dimensions (L × W × H) | 6000 × 2050 × 1600 mm | 5500 × 1950 × 1400 mm |

The movable saw head is powered by an imported servo motor with a precision gear-and-rack system, offering fast movement, full closed-loop control, and high positioning accuracy.

The saw blade is directly connected to an imported motor, using a lever-swing cutting motion that ensures smooth, stable performance and clean cuts.

The blade feed mechanism uses a pneumatic-hydraulic damping cylinder for steady, vibration-free operation and precise cutting results.

Equipped with a high-quality industrial control computer capable of directly receiving and processing external data for efficient automation.

The follow-up material support frame features a compact structure, minimizing floor space while ensuring consistent support during cutting.

Each saw head includes dual pneumatic cylinders for firm, secure clamping of profiles, enhancing both safety and cutting precision.

The machine automatically performs both ultra-short and ultra-long cuts, increasing adaptability across production requirements.

WhatsApp us