Close

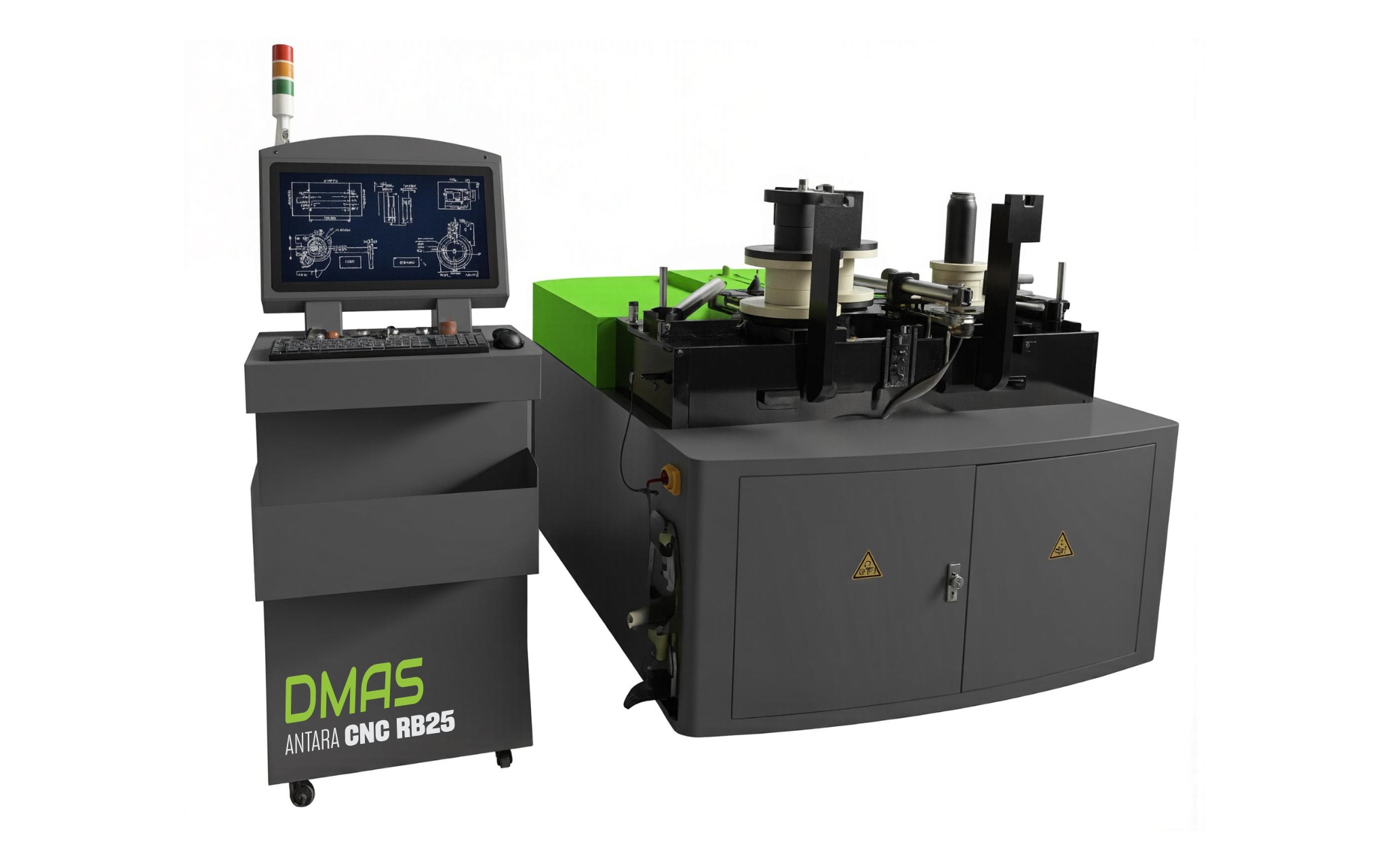

The DMAS Profile Bending Machine is engineered for precision forming of metal profiles across a wide range of cross-sections and materials. Using servo-driven rollers, photoelectric positioning, and CNC-controlled feed mechanisms, it delivers consistent, repeatable bending performance with exceptional accuracy.

Operating under the three-point rounding principle, the machine automatically adjusts roller displacement via servo control to form profiles into the desired radius in one or multiple passes. The entire system is fully synchronized through a CNC control unit that manages roller motion, feed rate, and bending pressure under a closed-loop system, ensuring high thrust, precision, and reliability.

Item |

Specification |

|---|---|

| Power Supply | Three-phase 380V, 50Hz / 60Hz |

| Total Power | 11 kW |

| Y-axis Push Rod Thrust | 25 T |

| Y-axis Repeat Position Accuracy | 0.01 mm |

| Max. Torque on X-axis | 6000 N·m |

| Axis Spacing | 400–800 mm |

| Min. Bending Radius | R = 150 mm |

| Shaft Diameter | 80 mm |

| Dimensions (L × W × H) | 1500 × 1400 × 1500 mm |

| Total Weight | 1800 kg |

| Max. Cross-section of Processed Steel Pipe | Square: 80 × 80 × 5 mm Circular: Φ80 × 5 mm |

| Max. Cross-sectional Area | 16,000 mm² |

| Max. Width (W) | 250 mm |

| Max. Axial Height (H) | 300 mm |

WhatsApp us