Close

At DMAS, our vision extends beyond machinery — we provide a complete ecosystem of complementary equipment designed to support, optimize, and enhance every stage of aluminum door and window manufacturing.

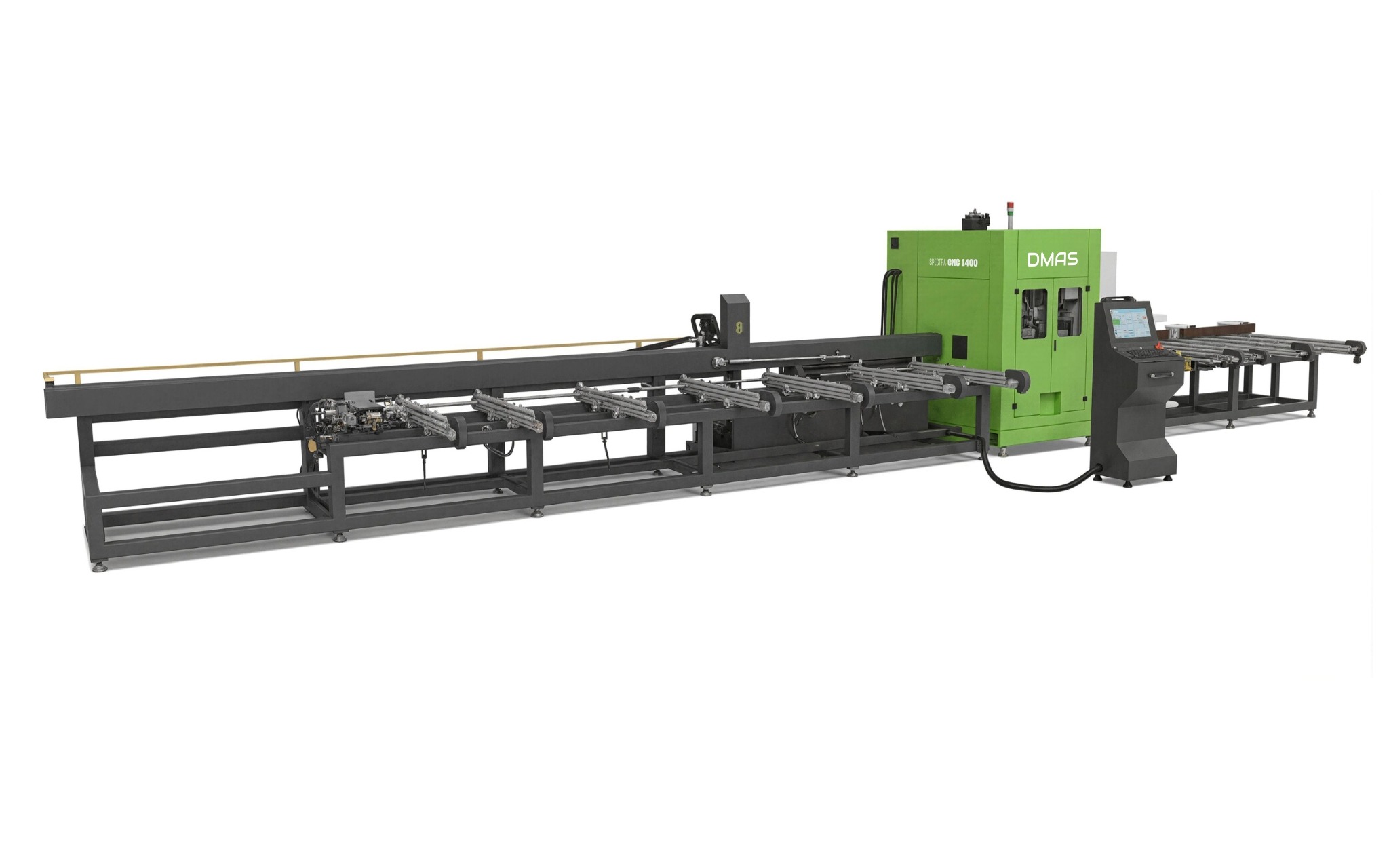

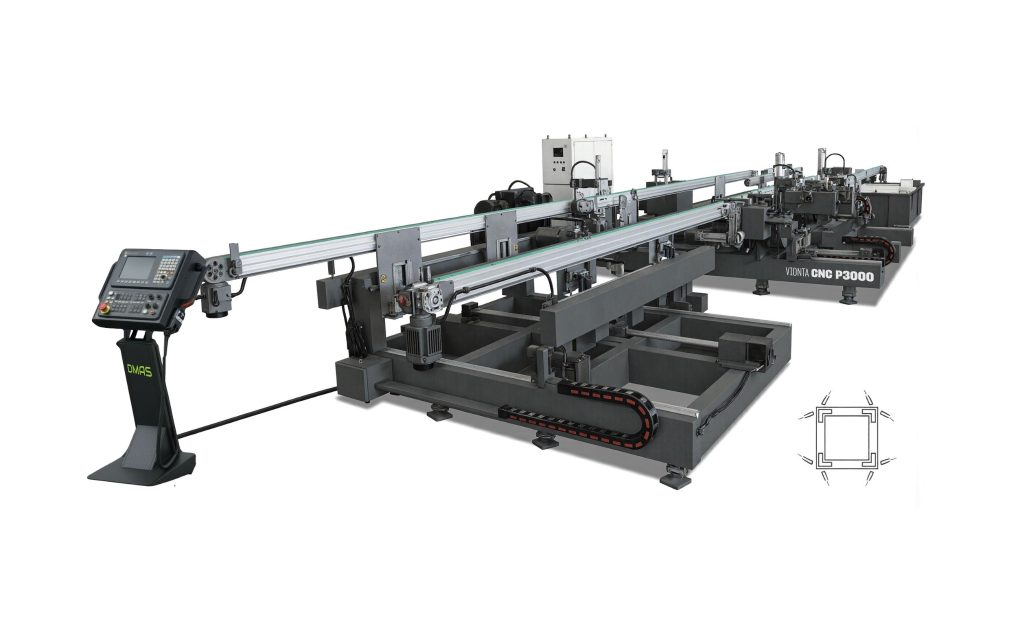

This advanced processing line is designed for automated fabrication of aluminum system doors and windows, providing seamless integration from profile feeding to finished output.

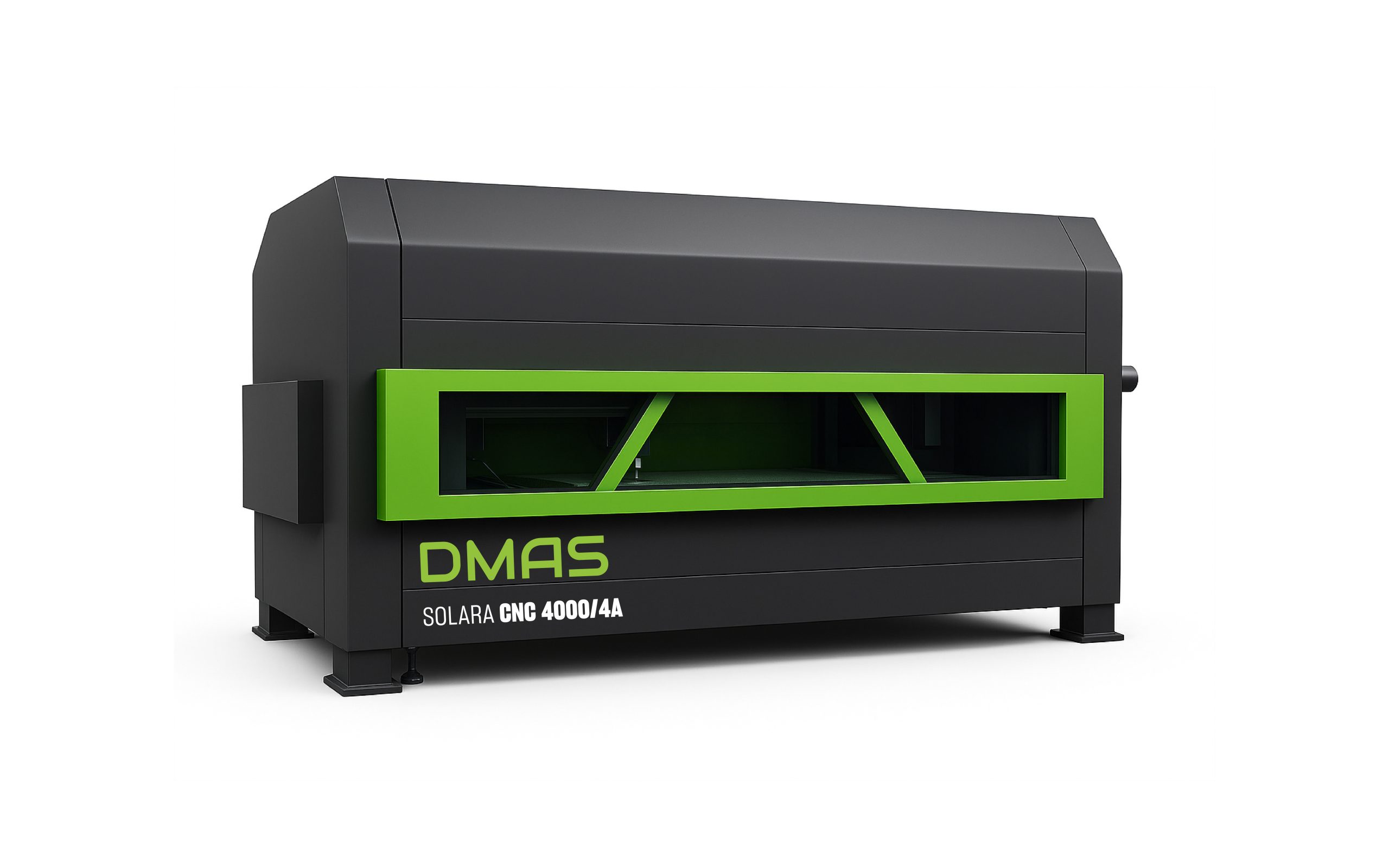

Designed for high-precision machining of aluminum profiles, this compact processing unit combines cutting, milling, and drilling in one automated system, featuring servo-controlled motion.

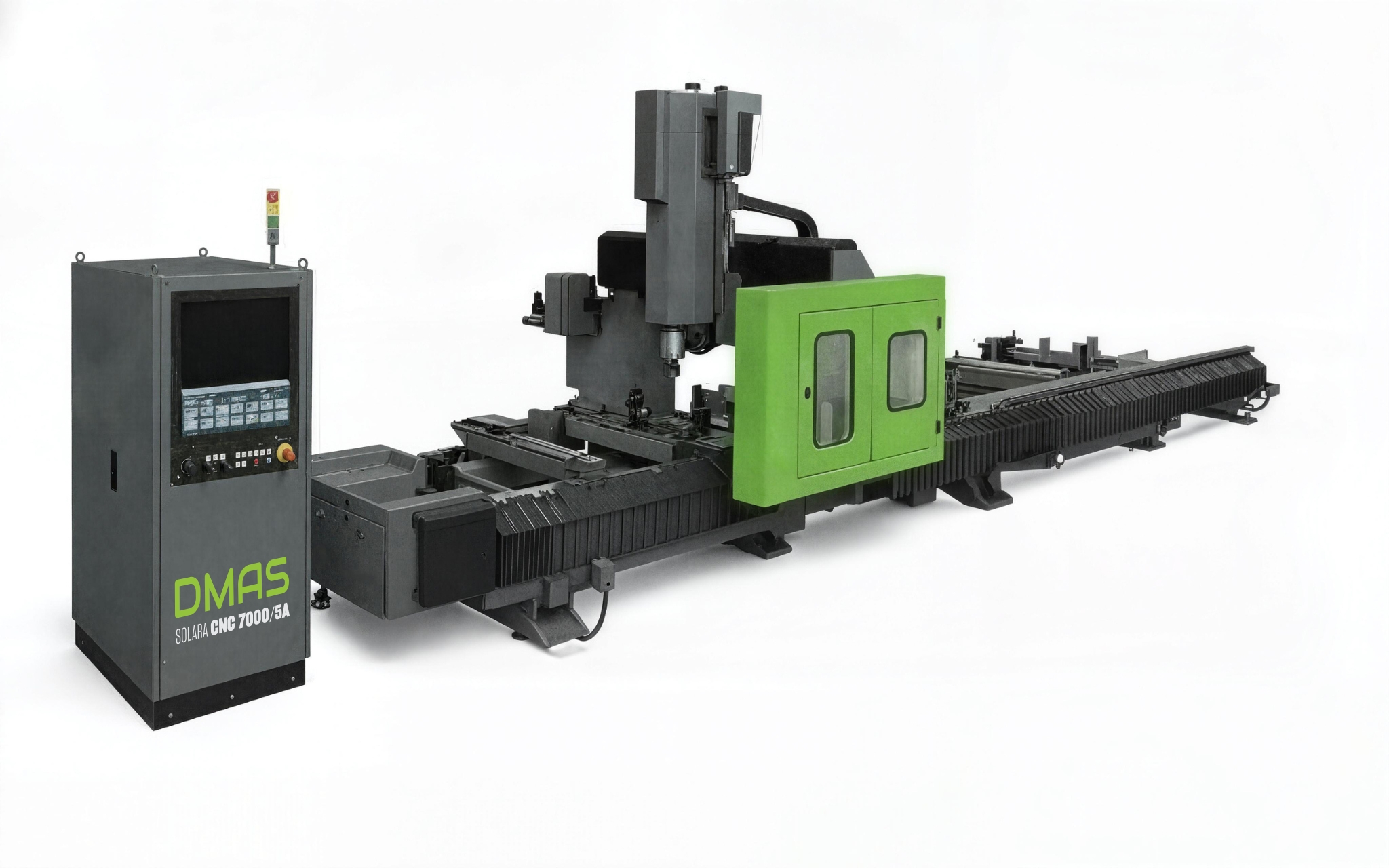

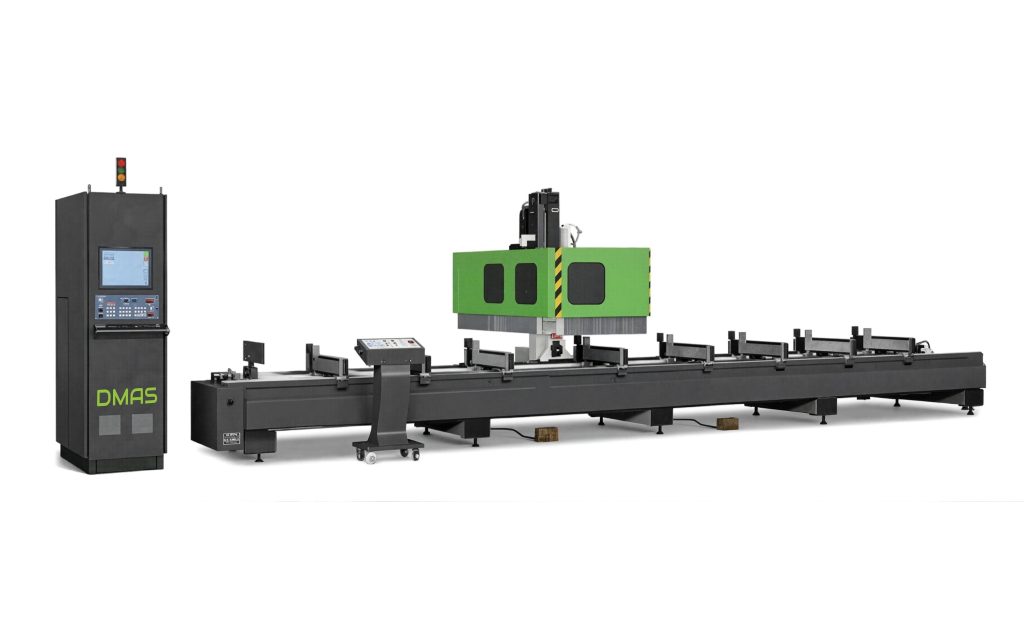

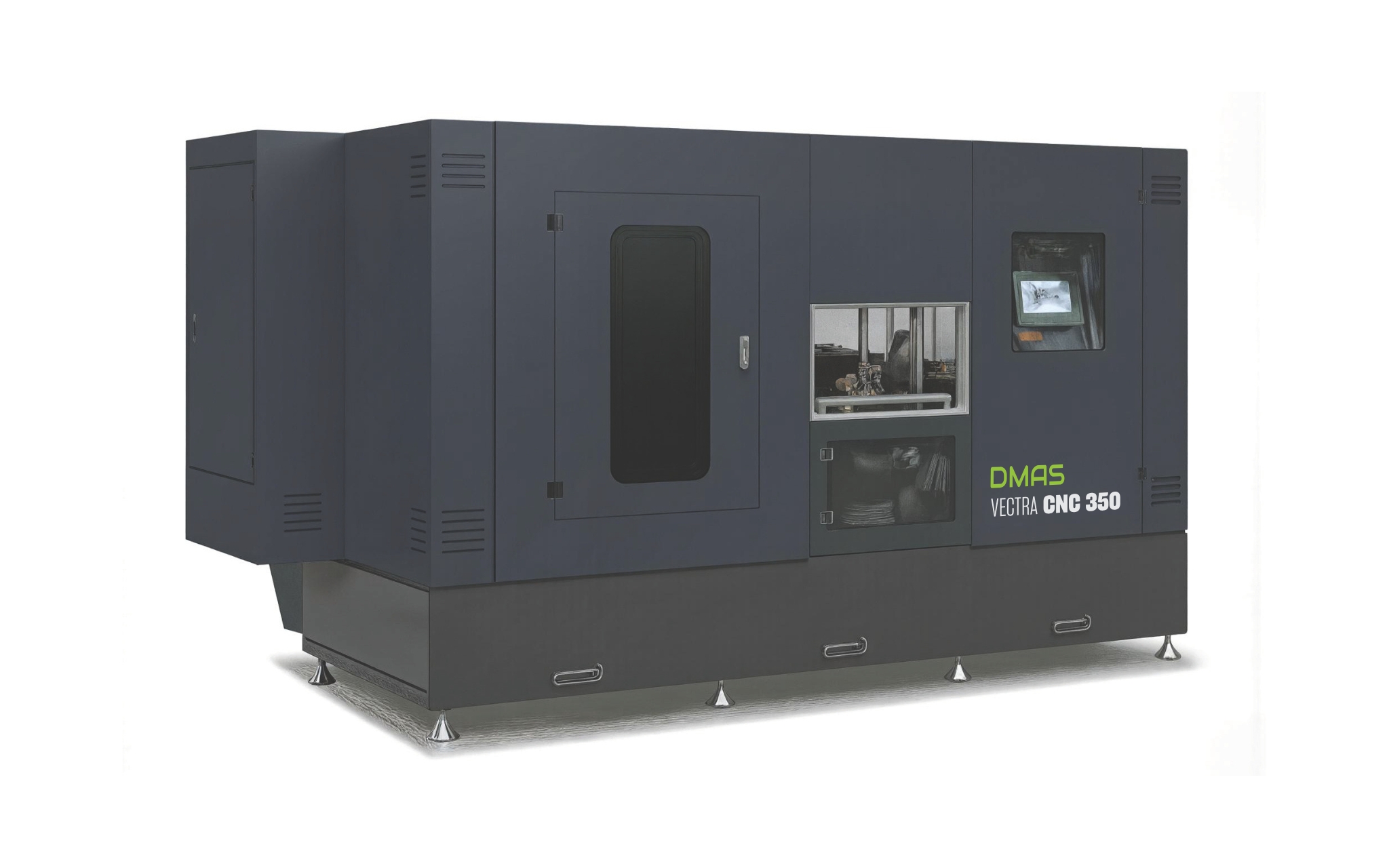

When design meets complexity, precision becomes essential. Our Advanced Drilling & Milling Centers are engineered to meet that challenge — combining power, stability, and intelligent control for high-performance machining of aluminum profiles.

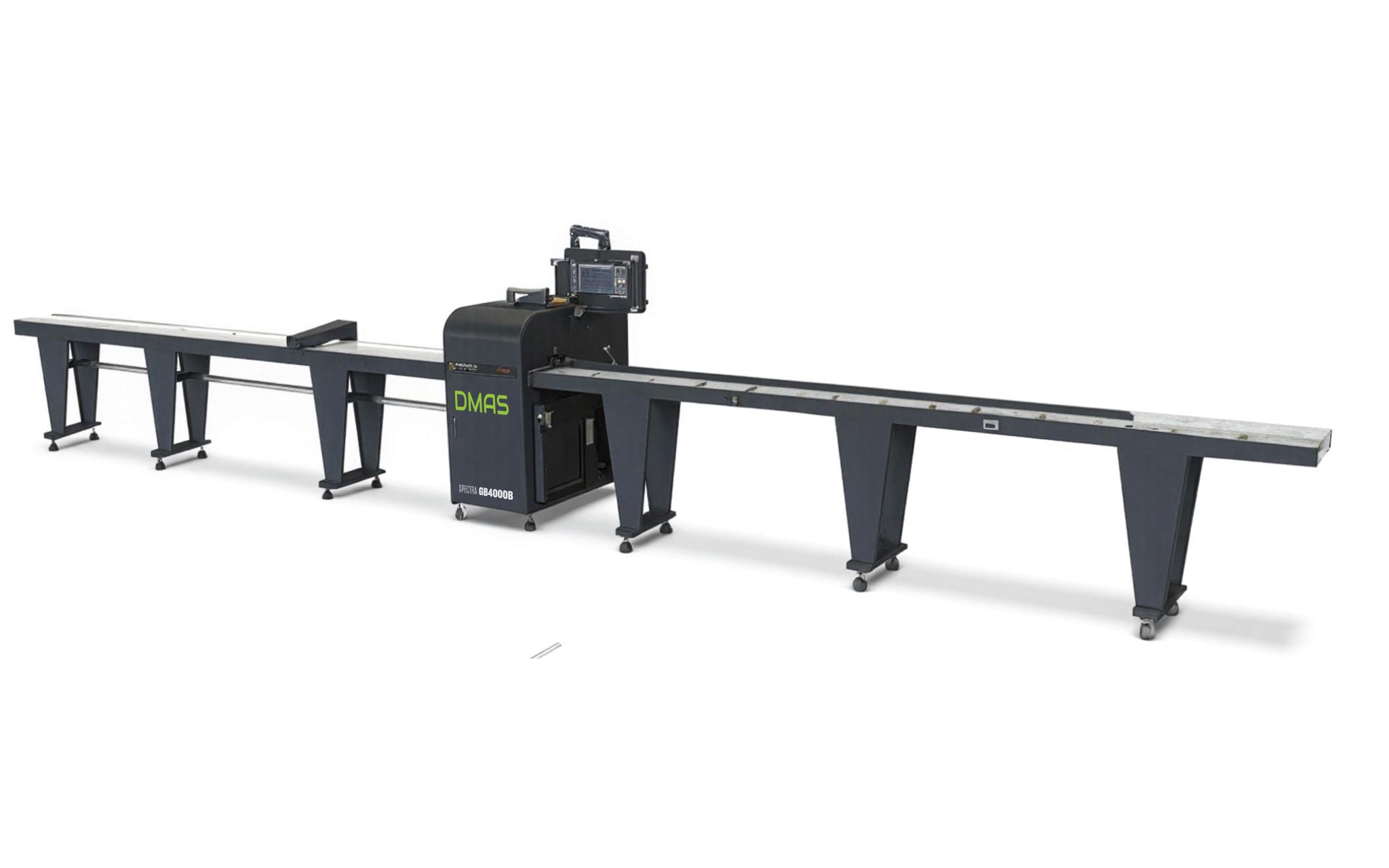

Cutting marks the beginning of every perfect frame. Our Precision Cutting Systems have been designed to set the standard for dimensional accuracy and process reliability in the fabrication of aluminum doors and windows. They ensure sharp, clean cuts, ready for immediate assembly without additional finishing or correction.

The Transom Notching Saw is a precision cutting system engineered for automated processing of transom and mullion notches in aluminum and light alloy profiles. Built for high-output production, it combines servo-controlled accuracy, sturdy construction, and intelligent CNC control to ensure clean, burr-free cuts and precise joint alignment for architectural framing systems.

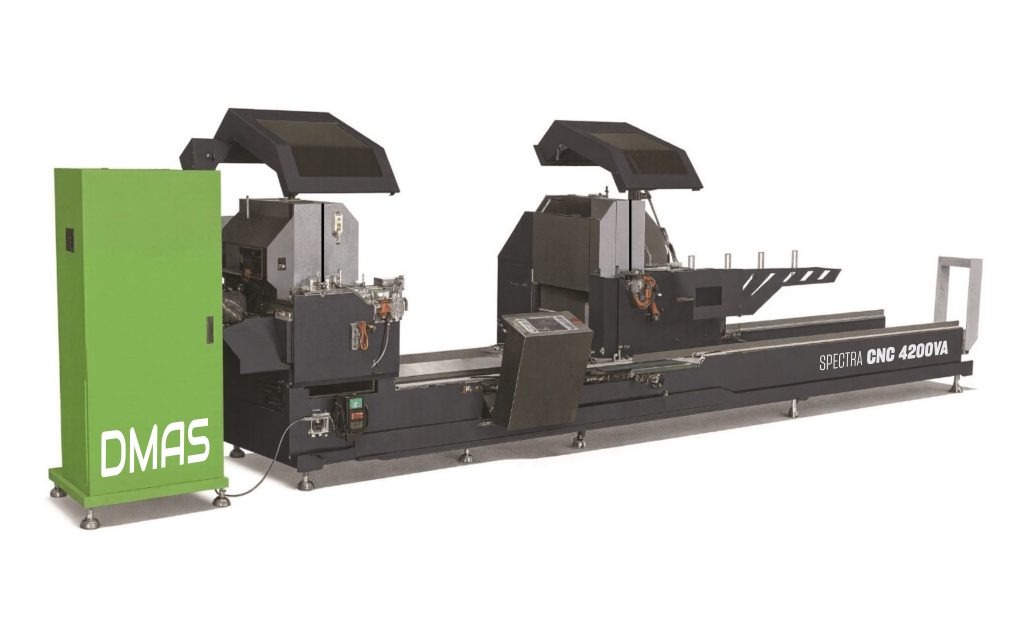

The CNC Arbitrary Angle Joint Saw is designed for multi-angle cutting and miter joint processing of aluminum profiles used in doors, windows, and façade structures. Its dual-head design with servo-controlled rotation allows high-precision cuts at any programmed angle, and seamless ERP/MES integration makes it ideal for automated production lines and digital fabrication centers.

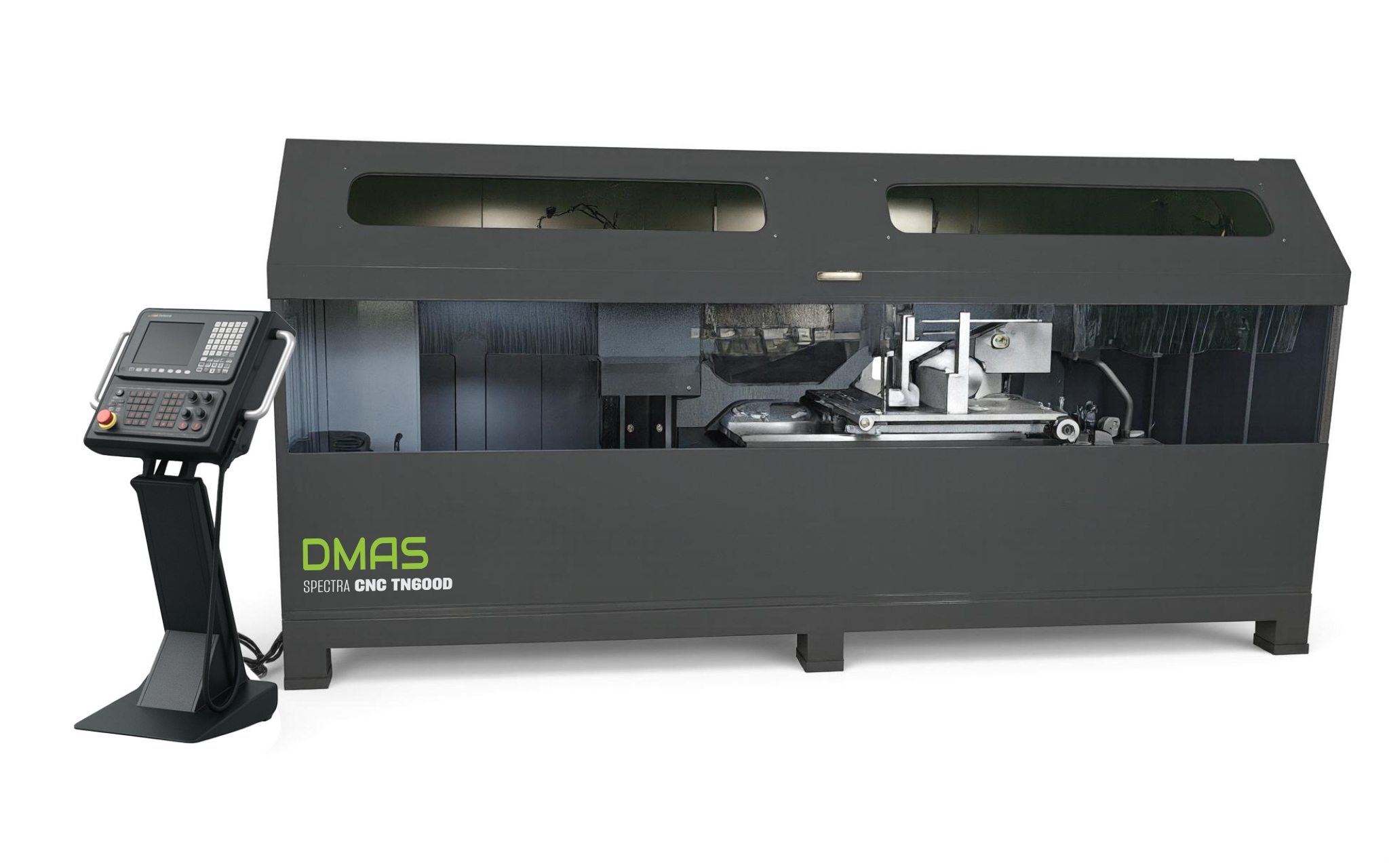

DMAS End Milling Systems are engineered for precision end-face machining of aluminum profiles used in system doors, windows, and curtain wall assemblies. They ensure perfect alignment, clean cuts, and exact dimensional matching between frame and sash connections, providing the foundation for structural integrity and high sealing performance.

The DMAS Double-Head End Milling Center combines profile length cutting and end-face milling in a single high-efficiency system. Designed for simultaneous dual-end processing, it enables cutting and milling of both profile ends in one clamping cycle.

Designed for precision end-face finishing of aluminum doors, windows, and light industrial aluminum profiles, this machine ensures clean, accurate cuts and perfect surface alignment, serving as a crucial component of high-quality assembly operations.

The DMAS Automatic End Milling Machine is engineered for high-precision forming of aluminum profile end faces, step faces, and grooves. Built for productivity and consistency, it enables simultaneous clamping and milling of multiple profiles, ensuring efficient continuous production.

The DMAS Automatic End Milling Machine is designed for high-precision forming of aluminum profile end faces, step faces, and grooves. Its adjustable milling cutter system moves up, down, left, and right to adapt to profiles of varying shapes and sizes, while the automatic feed and positioning system.

When design meets complexity, precision becomes essential. Our Advanced Drilling & Milling Centers are engineered to meet this challenge, combining power, stability, and intelligent control for high-performance machining of aluminum profiles.

DMAS offers a complete range of specialized aluminum fabrication equipment designed to enhance production workflow and ensure precision at every stage of profile processing. Each unit combines robust engineering, intuitive control, and high reliability, enabling operators to perform complex forming, cutting, and joining operations with exceptional accuracy and repeatability.

Designed for precision, performance, and productivity, our CNC Router is a high-efficiency machining solution for aluminum, composite panels, wood, and other non-ferrous materials. With a robust welded steel structure and advanced motion control system, it delivers exceptional rigidity, stability, and long-term accuracy.

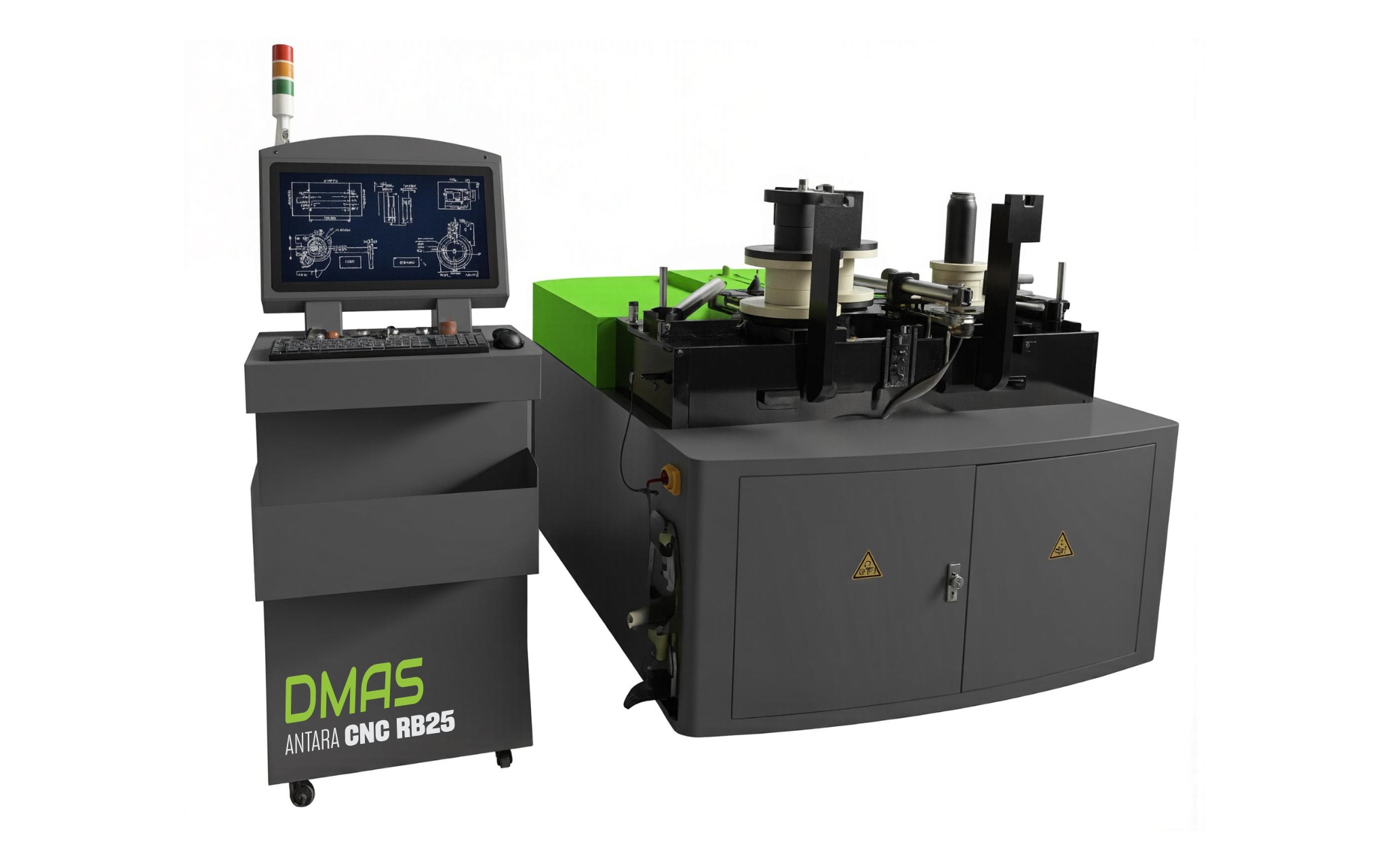

The DMAS Profile Bending Machine is engineered for precision forming of metal profiles across a wide range of cross-sections and materials. Utilizing servo-driven rollers, photoelectric positioning, and CNC-controlled feed mechanisms, it delivers consistent, repeatable bending performance with exceptional accuracy.

The DMAS Combination Punching Machine is designed for high-precision punching, notching, and shaping of aluminum profiles used in doors, windows, façades, and curtain wall systems, delivering speed, accuracy, and versatility.

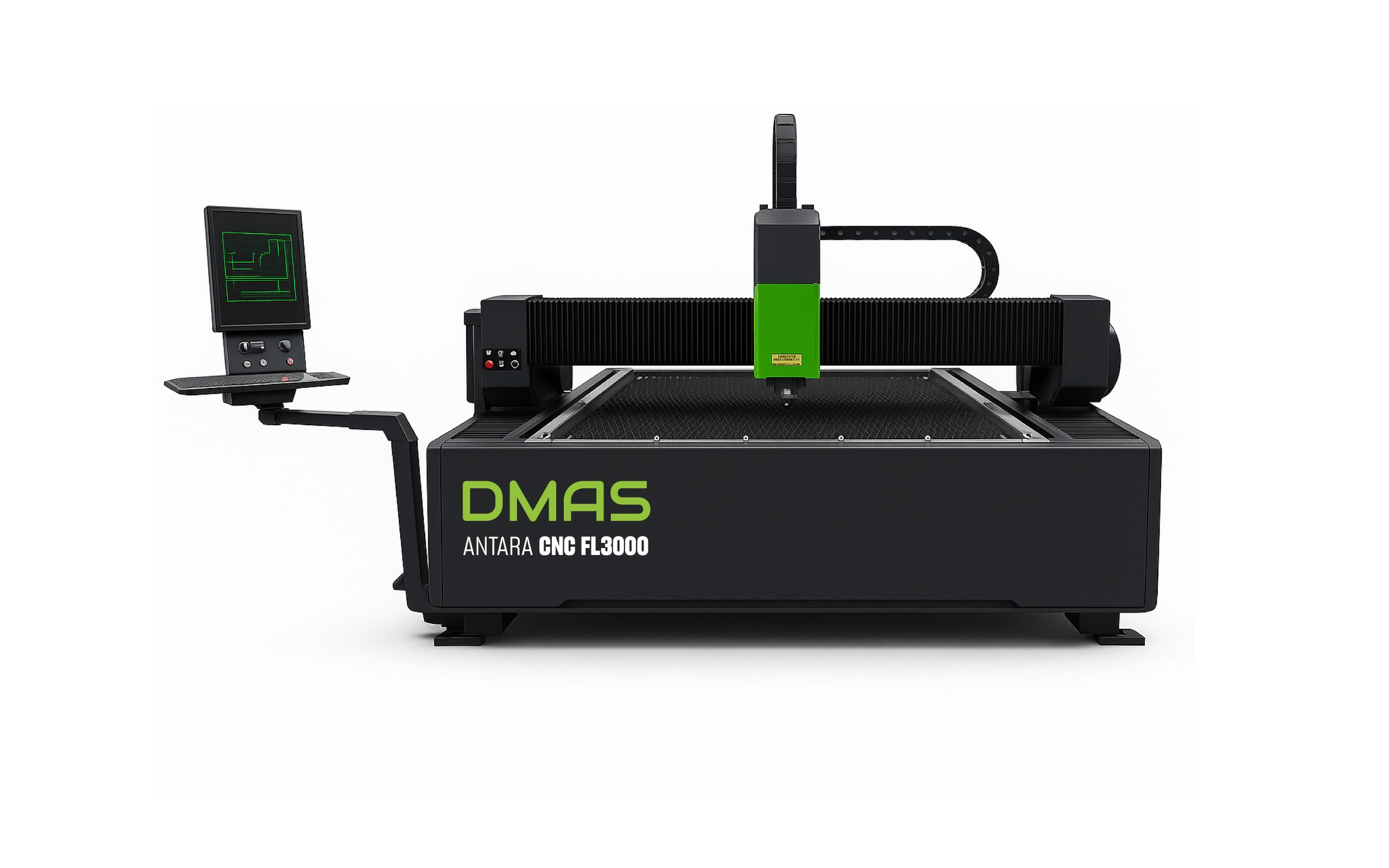

The CNC Fiber Laser Center is a high-precision system for cutting metal sheets and profiles with exceptional accuracy, speed, and efficiency. Equipped with advanced fiber laser technology, it delivers clean edges and minimal heat-affected zones, ensuring superior cutting quality for stainless steel & carbon steel.

This Fiber Laser Cutting Machine is designed for high-precision, high-speed cutting of steel and other metal sheets. Featuring an advanced 3 kW fiber laser source, it delivers exceptional beam quality, fast piercing, and smooth edges with minimal thermal distortion.

WhatsApp us