Close

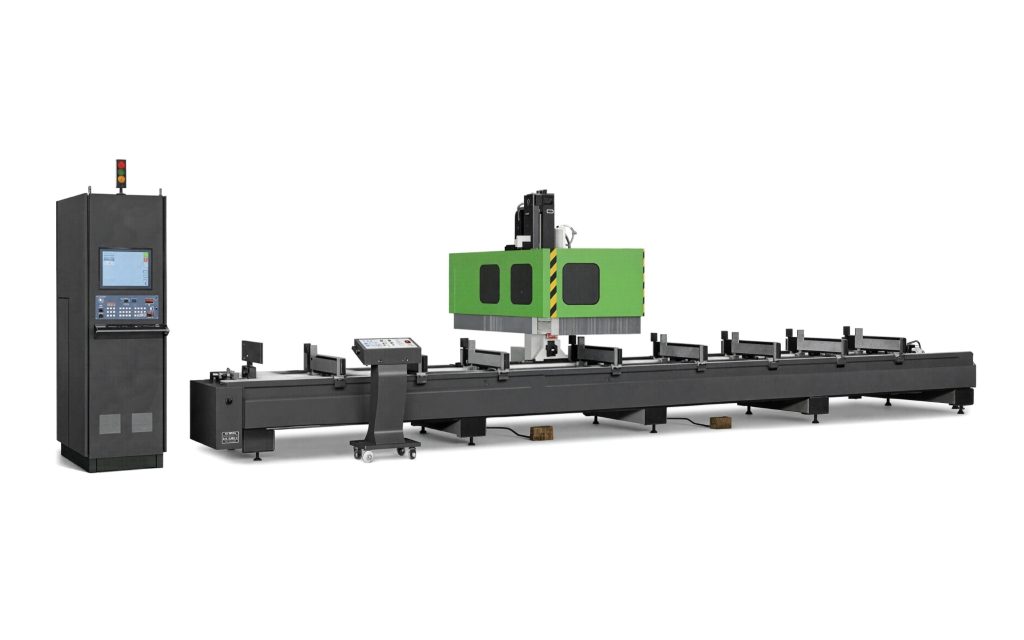

Developed for comprehensive aluminum profile processing, the system combines milling, tapping, drilling, and slotting operations to perform complex tasks such as launder cutting, mounting hole creation, locking slot machining, and other precision openings.

Designed for the production of diversified curtain walls and aluminum doors and windows, it adapts effortlessly to different profile geometries and architectural requirements. Equipped with a 4-axis high-speed CNC configuration, the system enables multi-directional processing without the need for repositioning, ensuring faster cycle times and superior accuracy.

Item |

Specification |

|---|---|

| X-Axis Travel | 7000 mm |

| Y-Axis Travel | 1400 mm |

| Z-Axis Travel | 320 mm |

| X-Axis Speed | 0 – 100 m/min |

| Y-Axis Speed | 0 – 30 m/min |

| Z-Axis Speed | 0 – 20 m/min |

| Spindle Speed / Power | 0 – 18,000 rpm / 7.5 kW |

| Gyrating Range | -90° ~ 0° ~ +90° |

| Cutter Max Length | 110 mm |

| Saw Blade Diameter | Φ80 – Φ150 mm |

| Air Pressure | 0.5 – 0.8 MPa |

| Power Supply | 380 V / 50 Hz |

| Total Power | 13 kW |

| Cutter Quantity | 8 |

| Lubrication & Cooling | Automatic Lubrication System |

| Work Area (W × H × L) | 650 × 200 × 7000 mm |

| Overall Dimensions (L × W × H) | 8000 × 2350 × 2550 mm |

WhatsApp us