Close

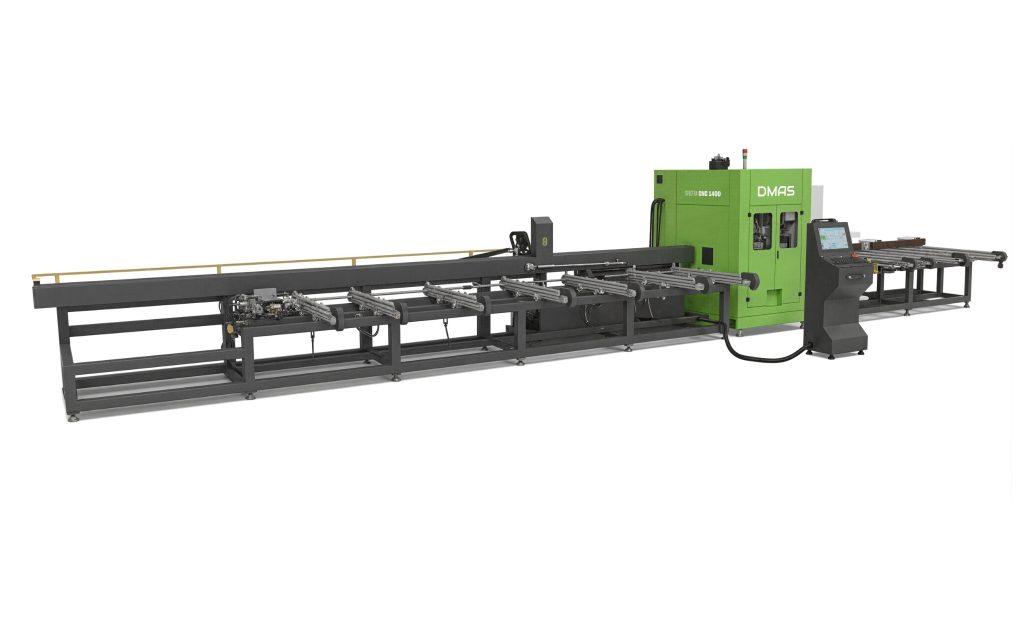

This advanced sawing system is engineered for the precise cutting of aluminum door and window profiles. It supports continuous processing of up to eight profiles simultaneously, delivering accurate ±45° and 90° cuts with exceptional consistency.

Equipped with an automated feeding, counting, and discharging system, the machine significantly reduces manual handling while maximizing throughput. Its robust mechanical structure and precision control system ensure stable operation, superior cutting accuracy, and high production efficiency—making it a reliable choice for modern aluminum fabrication lines.

Specification |

Value |

|---|---|

| Cutting Motor Power | 3 × 3.0 kW |

| Feeding Motor Power | 0.75 kW |

| Discharge Motor Power | 0.75 kW |

| Motor Rotary Speed | 2800 r/min |

| Input Power | 380 V / 50 Hz |

| Working Air Pressure | 0.5 – 0.8 MPa |

| Blade Specification | φ500 × φ30 × 4.4 mm Z = 120 |

| Cutting Length | 30 – 120 mm |

| Cutting Width | 30 – 120 mm |

| CTM Length | 350 – 6000 mm |

| Cutting Angle | ± 45° / 90° |

| Cutting Angle Accuracy | ± 5° |

| Length Accuracy | ± 0.2 mm |

| Repeat Locating Length Precision | ± 0.05 mm |

| Overall Dimension (L × W × H) | 13600 × 3000 × 2200 mm |

Ensures uninterrupted material handling and precise positioning throughout the cutting cycle.

Provide smooth, stable, and accurate motion, minimizing vibration and ensuring long-term reliability.

Guarantees high feeding accuracy and consistent performance.

Delivers smooth, steady cutting with superior precision and reduced maintenance requirements.

Enhances cutting efficiency, accuracy, and overall production quality.

Offers stable and reliable operation, supporting fully automated ±45° and 90° cutting with continuous, high-efficiency performance.

Protects the operator while maintaining a clean and controlled working environment.

Enables automated labeling and traceability within digital production systems.

WhatsApp us