Close

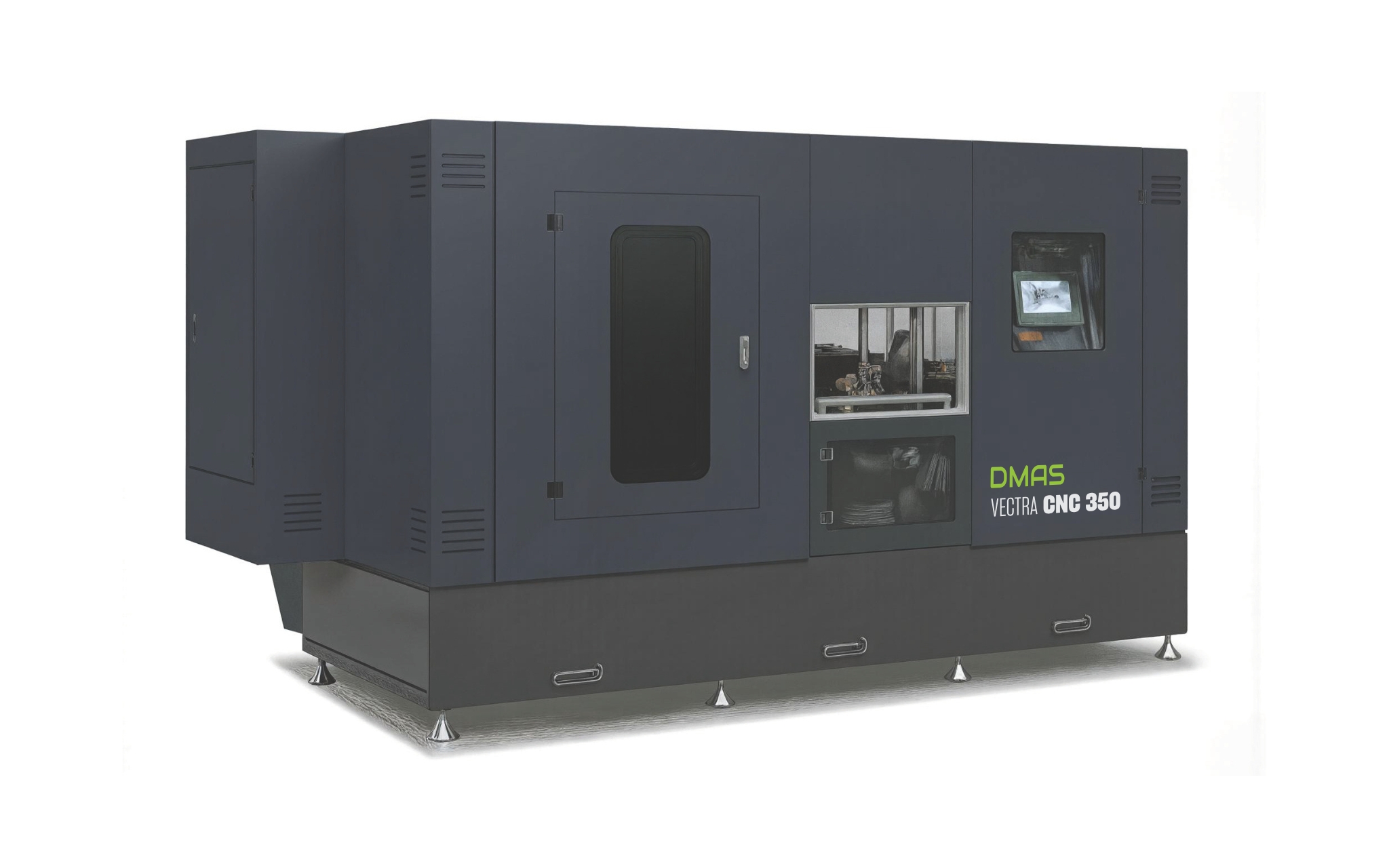

Designed for precision end-face finishing of aluminum doors, windows, and light industrial aluminum profiles, this machine ensures clean, accurate cuts and perfect surface alignment, making it an essential part of high-quality assembly operations.

Controlled by an advanced numerical control system, it offers easy programming, high compatibility, and superior efficiency and reliability for continuous industrial use. Available in 5-axis and 7-axis configurations, the machine provides exceptional flexibility to handle complex profile geometries and multi-angle machining requirements.

Specification |

CNC 350/5A |

CNC 350/7A |

|---|---|---|

| Power Supply | 380 V / 50 Hz | 380 V / 50 Hz |

| Motor Total Power | 10 kW | 15 kW |

| Motor Rotary Speed | 2800 r/min | 2800 r/min |

| Working Air Pressure | 0.6 – 0.8 MPa | 0.6 – 0.8 MPa |

| Air Consumption | 50 L/min | 60 L/min |

| Diameter of Milling Cutter | φ300 mm (2 pieces) | φ300 mm (3 pieces) |

| Milling Depth | 80 mm | 80 mm |

| Saw Blade Specification | φ350 mm (1 piece) | φ350 mm (1 piece) |

| Cutting Height | 200 mm | 200 mm |

| Workbench Size | 476 × 320 mm | 510 × 310 mm |

| Cutting Angle | 0° – 90° | 0° – 90° |

| Overall Dimensions | 3100 × 1530 × 1800 mm | 3520 × 1780 × 1800 mm |

WhatsApp us